Engineering innovative, cost-

effective lab automation.

Laboratory Automation is in our DNA

At Robotyx, we understand that laboratories can experience limitations in resources. That’s why our team focuses on our guiding principles to deliver to your needs.

Engineering experience you can trust

With more than 15 years of engineering experience, including building a high throughput automated genotyping lab, our team is ready and able to support your automation needs.

Trusted by automation labs at:

Get started with Robotyx services

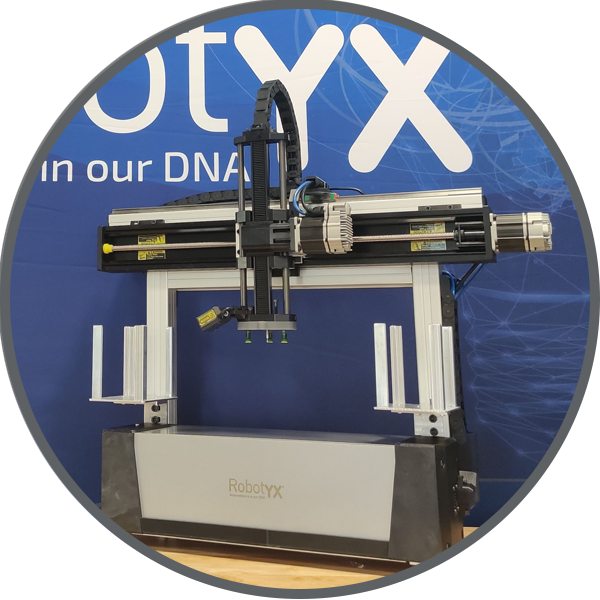

We are passionate about delivering lab automation equipment that enables automation and efficiency for your team. Currently we offer the Robotyx Plate Stacker and Plate Mover. Additionally, we can create a tailored solution for your lab. Let us know what problem you need solved and our team of experts can create a custom solution for you.

Plate Stacker

Plate Mover

Tailored Services

About Robotyx

Robotyx is an OEM sister company of Transnetyx, an automated genotyping service that provides 99.97% accuracy and results in 24 or 72 hours. The Transnetyx lab is highly automated and utilizes RT-PCR using proprietary lysing and DNA isolation using custom Taqman probes, processing more than 90,000 samples a week.

Transnetyx started with a few Tecans and a custom machine built by another OEM. However, as Transnetyx grew, it became apparent that the laboratory automation could not run 24/7 with the existing setup. Breakdowns began to cause loss of time and money. At that point, the idea of Robotyx was born.

The Robotyx team began producing custom integrations using industrial robotic arms. As we progressed, more and more of the integration became custom. We started designing, building, and programming our instrumentation from scratch to handle the rigors of our production environment and create systems that worked for our process. In 2020, Robotyx moved into a separate Nashville location to design and build instrumentation away from the day-to-day issues of running a production lab. It is here that we creatively solve problems on limited budgets and tight timelines. We focus on designing and building the simplest yet robust system to accomplish the requirements and create cost-efficient, reliable instruments.